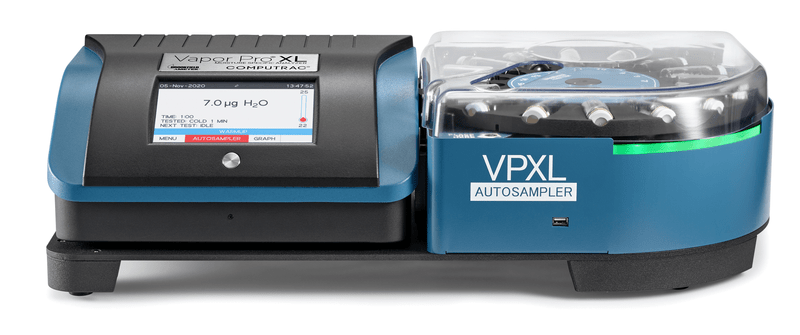

Computrac Vapor Pro XL

- Availability:

- Lead Times Vary by Product

Description

The Next Generation in Chemical-Free Moisture Analysis. Improved repeatability, precision, flexibility, and an advanced user interface. Vapor Pro® XL (VPXL) is the latest in moisture specific analysis technology from Computrac® is ideal for nearly any application in which Karl Fischer titration is used.

Features

- Zero Chemical Reagents

- 7” color LCD touchscreen

- Stepped Temperature Testing

- Multiple Sample Vial Sizes

- Stores data up to 250 test programs

⚠️ California Proposition 65 Warning

This product can expose you to chemicals including Titanium Dioxide, a chemical in Loctite 242, which is known to the State of California to cause cancer, birth defects, or other reproductive harm. For more information, click here or visit www.P65Warnings.ca.gov.